Ductile Iron Dual Plate Full Lug Type With Full Rubber Check Valve

TC10-DI

DI Solid Lug type with fully lined dual check valve

Full lug with full rubber design dual plate check valve is a shorter face-to-face dimension and dual plate design. Versus conventional swing check valves, the series valve have the advantages of no leakage toward outside, cost saving, any installation position, seal performance, minimal line shock, lower pressure loss and zero seat leakage.

Full Lug type dual plate check valve is suitable for the environment where the space is small, because the flange hole has tapping

Full lug with full rubber design dual plate check valve design offers the twin advantages of No Water Hammer and Non Slam simultaneously.

All features put together make the full lug type dual plate check valve with full rubber one of the most efficient design.

Lug type valves are provided with threaded bolting holes in accordance with API 594,ASTM,JIS,ISO.

Lug type has its own tapped holes which allow the bolts to be threaded into it from both sides. This allows the dismantling of any side of the piping system without removal of the duo check valve in addition to keeping the service on the other side.

Features

- Full Lug Lining design, mount between flanges by bolt which through disc and body.

Specification

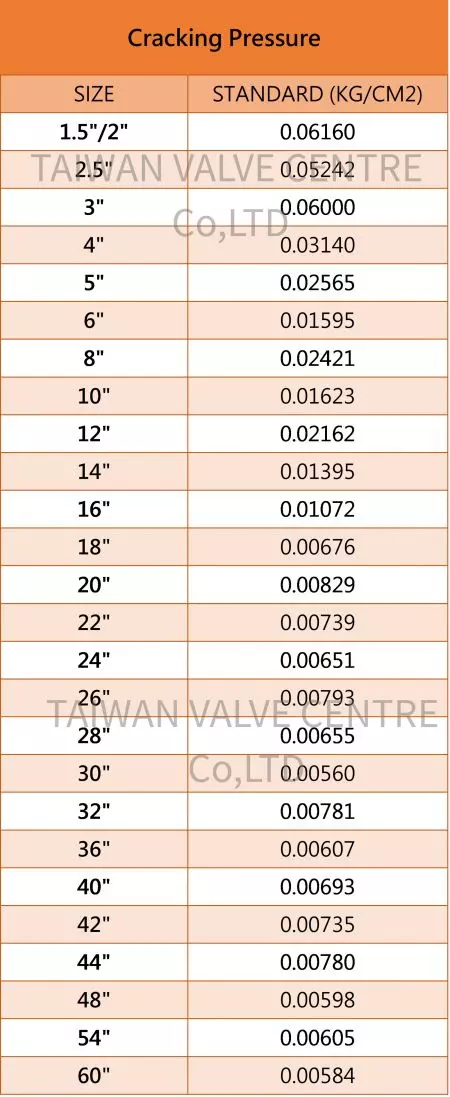

- Size: 2" ~ 60" (DN50 - DN1500)

- Pressure Rating For ASME: 125# ~ 600# Suit For ASME / MSS / API Flange

- Pressure Rating For ISO: PN10 ~ PN40 Suit For ISO Flange

- Pressure Rating For JIS: 5K ~ 20K Suit For JIS Flange

- Material:CI,DI,WCB,CF8,CF8M,ALBC3,A8904A(MOQ)

- Designed in accordance with API 594.

- End Connection: Wafer (TC1), Lugged (TC7), Flanged (TC4)

- (Other flange connection please contact Taiwan Valves Centre Co., Ltd.)

- *Technical information is only for reference. Taiwan Valves Centre Co., Ltd. reserves the right to change without previous notice.

Applications

- Soild Lug with full lining type check valve is suitable for sea water, cooling water..ext. Used in Ship Building, seawater desalination, seawater cooling system.

- Dual plate Full Lug type check valve is suitable for high temperature and high pressure environment, like Petrochemical, Refinery or power plant.

- Applied in Water Supply Systems, Fire Water Systems, Cooling Water, Chilled / Hot Water Systems, Boiler Feed Water, Sea Water, Potable Water, Raw Water etc.

- Suitable for gas, like LPG, LNG, Sour Gas Low Temperature, Cryogenic Applications

- Used in pharmaceutical, Power and other industries

- Solid lug type dual check valve can use for liquids and gasses in general services, on-/offshore applications, etc.

- In Nuclear Industry, Dual Check Valve used for feed water control system, make-up water or other.

- Also use in steam, oil, nitric acid, acetic acid, strong oxidizing medium and urea, different medium should chose different material.

- Full rubber type check valve suitable for seawater, water, cooling water pipeline and…etc.

- The full rubber lined usually used in shipyard, ship plant, seawater desalination, seawater-cooling system.

- The rubber separate medium and the valve of body in order not to contact directly. The full lining type check valve can be used for high concentration brine or acidic medium.

- Full lining type check valve widely applied for water conservancy facilities, sewage treatment plants, and industrial or residential construction industries.

- Dual plate wafer type check valve with full rubber can suitable for pump, sewerage, and reservoir flood control, etc.

- Used in waterproof systems, discharge system, pump, etc.

More Knowledge about TVCCL valve:

TVCCL full rubber type check valve’s material is divided into two choices, NBR and EPDM. Before use, you must pay attention to the temperature of the medium and whether there is a granular object in the medium. Because the rubber can't afford the high temperature and low temperature as well, it is recommended to use it at normal room temperature to avoid the rubber falling off or deforming; and owing to the rubber is unbearably worn, It is not recommended to use the full-rubber type check valve in the cement or the medium which has the presence of particulate matter in pipelines. The installation method is the same as the dual plate check valve. The only difference is that the flange surface of the full rubber type check valve is also covered with rubber, so it is not necessary to add a gasket to fix it.

The Full Rubber type check valve’s inner covering rubber, the medium and the body material are not in direct contact, and the rubber is separate into the medium and the valve body material, thereby achieving the acid resistance and corrosion resistance. The Full rubber type check valve body internal adopts an all-rubber design, which is not easily deposited or produced. And it also reduces the maintenance cost, but the disadvantage is that the rubber is not suitable to keep for a long-time in outside, even if the quality of the rubber is high, the aging phenomenon cannot be avoided.

More Knowledge about dual plate check valve:

Ductile iron, also known as ductile cast iron, ductile iron with the advantages of gray cast iron, and with a little steel advantages such as high strength, toughness, ductility, hardening, thermal workability, etc.…

Solid Lug Type check valve also called Full Lug type check valve. It is named the Lug type is because the shape is like the ear. Full Lug type is suitable for the environment where the space is small, because the flange hole has tapping, it can save the space occupied by the nut and the cost of the nut. Full Lug check valve has the same advantages and installation with Lug type, just the shape is different. Full Lug type Check valve is threaded (Flange holes by tapping). Also, after tapping the holes, it only needs the bolt to install, it can decrease the spent of Nuts on the contrary. Clamped between flanges with bolting passing through the body of a valve. The full lug type wafer type check valve's design that one end of the line can be taken off without having an effect on the opposing side. This can be executed by using flanges, along with two sets of lugs (bolts) that don't utilize nuts since each flange features its own bolts. It's also important to note that you don't need to shut down the entire system in order to clean, inspect, repair, or replace a lug wafer valve.

- Related Products

Dual Plate Wafer Type Check Valve with Full Rubber

TC1

Dual plate wafer type check valve with full rubber is usually used in seawater desalination...

DetailsDual Plate Lug Type Check Valve

TC6

The dual plate lug type check valve only takes 15-20 minute completely dissemble and reassemble...

DetailsDual Plate Full Lug Type Check Valve

TC9

Double disc lug type check valves are designed to ASME, JIS, ISO, AWWA...etc. specifications...

DetailsDual Plate Flange Type Check Valve with Full Rubber

TC5

Full rubber body dual plate flange check valves design with no external body penetrations eliminating...

DetailsDual Plate Lug Type Check Valve with Full Rubber

TC7

Lug type dual plate with full rubber lined check valve's body with full rubber lined can effectively...

Details- Files Download

Dual Plate Wafer Style Check Valve Installation and Maintenance Instructions

Installation and Maintenance Instructions for dual plate check valve

Download- FAQ

Q.What Is Check Valve?

TVCCL Check Valve is a dual plate check valve that conforms to API 594. TVCCL is known as one of the leading manufacturers of Valve in Taiwan since we established.A...

Q. How Do Install Double Disc Check Valve In Pipe?

Taiwan Valve Centre Co.,Ltd. is the professional dual check valve manufacturers in the Taiwan. This information concerning the installation and operation...

Q. What Kind Of Material TVCCL Stock For Dual Check Valve?

Materials Stocked for Dual Plate Check Valve by TVCCLTVCCL, a pioneer in valve manufacturing, has been at the forefront of the industry since 1998. Our expertise...

Ductile Iron Dual Plate Full Lug Type With Full Rubber Check Valve - DI Solid Lug type with fully lined dual check valve | Made in Taiwan Dual Plate Check Valves Manufacturer | Taiwan Valve Centre Co., Ltd.

Located in Taiwan since 1998, Taiwan Valve Centre Co., Ltd. has been a dual plate check valve manufacturer with all the valves sold to 1,500 clients in 80 countries worldwide. Their main valve products, including Ductile Iron Dual Plate Full Lug Type With Full Rubber Check Valve, dual plate check valves, dual plate full lining type, retainerless check valves, bypass check valves, short and long wafer check valves and spring wafer type for industries, such as oil, shipbuilding, seawater desalination, cooling system and nuclear.

TVCCL has a competitive pricing, reliable quality product and excellent after-sales support, well-down packing. We have received good reputation as being a well-known supplier in supplying reliable quality and competitive price check valves from customers. 20 years of experiences in producing dual plate check valve, excellent after-sales support, OEM / ODM, oil industry, shipbuilding, seawater desalination, cooling system, nuclear industry.

TVCCL, TAIWAN VALVE has been offering customers high-quality and durable industrial check valves for any applications since 1998, both with advanced technology and 25 years of experience, TVCCL, TAIWAN VALVE ensures each customer's demands are met.