Factory Profile

Taiwan Valve Centre Co., Ltd. focuses on ensuring product quality, delivering high-tech valves, and maintaining excellence in personnel, machinery, materials, processes, and the environment.

Taiwan Valve Centre Co., Ltd. providing customers with high-tech standard valves

At the forefront of TVCCL beliefs are “Talent Assets” and “Social Responsibility.” The combination of business concepts and corporate beliefs create the core of TVCCL that encourages us to embrace sustainable operations.

Upon entering the 21st century, through the 23 years’ tillage and development, TVCCL nowadays has been an international check valve, gathers research development, design, manufacture, inspection and marketing. TVCCL rank No.1 in the field of dual plate check valve in Taiwan.

Set up in 1998, Taiwan Valve Centre Co., Ltd. is a leading industrial valve manufacturer in Taiwan and has been exporting this line of products for more than 30 years to Japan, U.S., Europe, Singapore, Southeast Asia, and other nations all over the world.

Taiwan Valve Centre Co., Ltd. have professional valve production lines in Taiwan and other countries, which offer product design, mass production, quality assurance, and worldwide sales.

Factory Introduction

In order to have good team work and efficient communication, TVCCL office and factory has short distance that have consistent production process control. TVCCL is committed to pursuing the stable quality of the products, providing customers with high-tech standard valves, factory management in TVCCL, and paying attention to the comprehensive quality performance of personnel, machine, materials, procedures, and environment.

Starting from raw material into the factory to packaging and shipping, we pay attention to the strict quality and fast supply process of each process; establish complete inspection equipment / good quality production equipment / strict quality inspection process / smooth delivery mechanism,

TVCCL basic rule is “SAFE", and we do everything under safe. After that, personal training, equipment maintenance, material preservation, and environmental cleanliness are managed according to the principle of 6S.TVCCL has a "pragmatic and rigorous" work attitude, from doing sample trials to finished product supply, and standard operating procedures (SOP) are set for an operation on the production process. The on-site supervisors are supervised at any time by "walking management". To ensure the safety of personnel and the stability of production, we provide customers with the highest quality valves, the most accurate and fast delivery, and the highest level of pre-sales and after-sales service.

Friendly Environment

In addition, behind the factory, we also have our small farms to plant a variety of green plants; the art, humanities, and styles are presented in the company's internal conference rooms and offices, and the conference rooms and offices full of the painting that from different Taiwanese painters. The style of painting not only extends the visual space but also eases the meeting atmosphere in the office or in consultation with the client, to achieve the effect of relaxation of the body and mind.

TVCCL tries to create a comfortable working environment constantly. In the office environment, we can see green plants everywhere, not only visually enjoyment, but also achieve the improvement of body and mind through color psychology, so that employees not only increase the work efficiency, more able to maintain a happy mood.

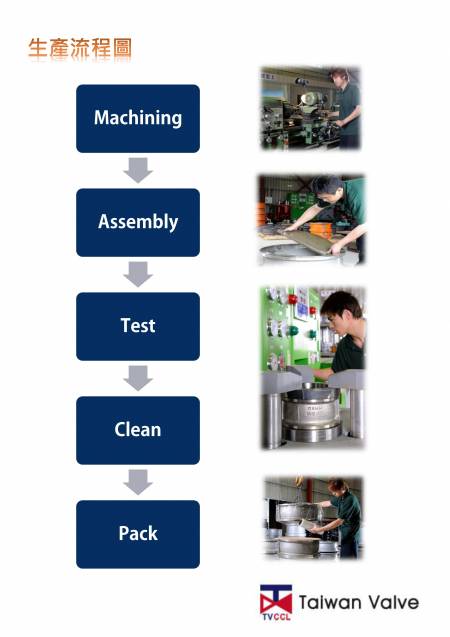

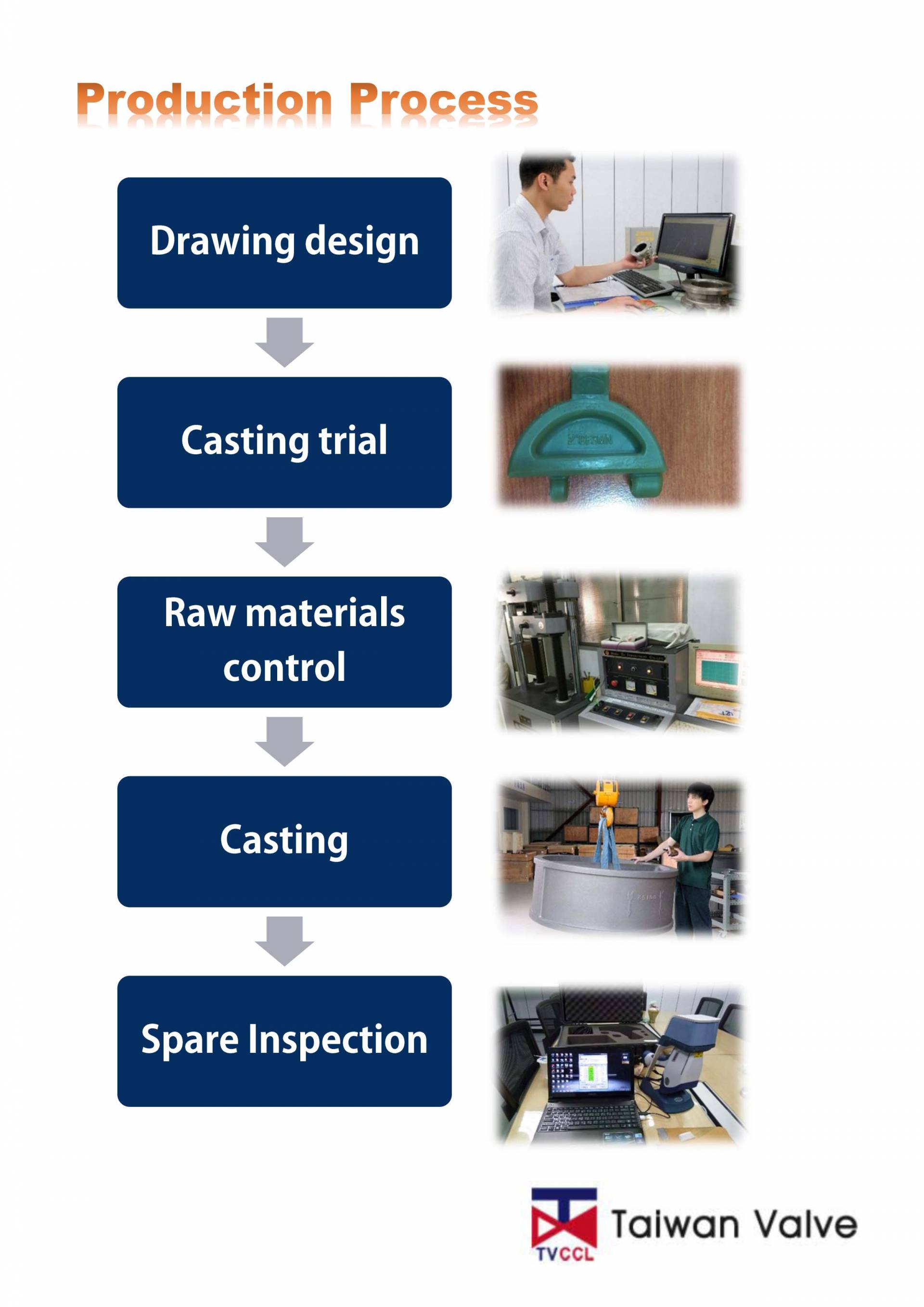

Production Process

1. After receiving the confirmed Order by the sales department, the Manufacturing department turns to “Production Order” and the establishment of a time schedule does control the production schedule. which is controlled by the production line and quality inspection.

2. During the assembly and inspection process, the quality control procedures are controlled to ensure the operation and product quality.

3. In order to shorten the waiting time for customers, the annual production plan of the management plan, regular quantitative production, effectively control the product safety stock, so that the shipping schedule is reduced to the shortest.

4. The materials and semi-finished products produced in the production process are all regulated by the “6S Management rules”, clearly indicating the name, specification, manufacturing number and the state of storage at that time, so as to avoid loss or misuse of the parts.

5. During the production inspection process, the relevant inspection records are carried out according to the inspection items in the “Machine Inspection Record Form”. The engineer signs or seals the instructions after the completion of the project, so as to facilitate the traceability of the after-sales service.

6. Maintenance of machinery and equipment used in the production process shall be carried out in accordance with the “Environmental Maintenance Procedures” to ensure that the production and sales process is not affected by adverse environments and appliances.

* The above production process uses ISO quality management system to strictly control product quality.

After Services

TVCCL Factory has not only to offer OEM, ODM, also we have provided the professional services as below:

1.Valve Testing Service:

TVCCL can follow the client’s demand to do the testing, not only International standard but also the client’s own testing requirement, we all can make the testing and offer the testing report or MTR(Mill Test Report) to TVCCL customers.

2.Repair/Maintenance service

TVCCL responsible for product after-sales service, as long as it is our company's products, the products all have the maintenance services; if not our products, TVCCL can still provide professional technical advice, to let customers as a reference.

Adhering to the quality policy of TVCCL, each valve must pass the test before shipping.

TVCCL Spirit

The mission of each member of the TVCCL is to build safe, high-quality products and to provide products that customers expect, as a long-term and reliable technology and capacity provider in the global valve industry. Providing high-quality products is always a top priority of TVCCL.

TVCCL guarantee service efficiency to all customers; for example, the technical team can propose the best efficiency and deliver the product in the shortest time. In the process of providing samples, the machining accuracy can make the sample more complete and exceed the customer's expectations. It takes only 20 days to confirm approval from the initial design to the technical drawings; this proves the efficiency of the company's operations

- Movies

- Movies