Q. How Do Install Double Disc Check Valve In Pipe?

Taiwan Valve Centre Co.,Ltd. is the professional dual check valve manufacturers in the Taiwan.

This information concerning the installation and operation of TVCCL Wafer Style, Dual Plate Check Valves. To ensure efficient and safe operation of TVCCL Dual Plate Check Valves.

This manual is general in nature and is not meant to take the place of an on-site, process engineer or pipe fitter.

Installation Procedure:

Preparation:

Ensure the system is depressurised and isolated from any energy sources.

Collect the required tools and equipment.

Assess the double disc check valve for any noticeable harm or imperfections.

Confirm that you have the right valve size and type for the intended usage.

Check the dual plate check valve to ensure that the pressure and duo check valve materials are appropriate for the intended use.

Clean the Pipeline:

Clean the pipeline area where the valve will be installed to remove any debris, rust or scale.

Ensure that the flange surfaces in the pipeline are clean and defect-free

Internal surfaces and parts of the dual plate check valve should be thoroughly cleaned and cleared of any debris prior to installation.

Positioning the Valve:

The double disc check valve created to fit amid two flanges in a piping system.

Place the valve between the flanges, before installing the valve, it is essential to determine the flow direction. This can be done by aligning the arrow on the side of the valve with the flow direction. Incorrect installation will result in the flow being blocked.

Bolting:

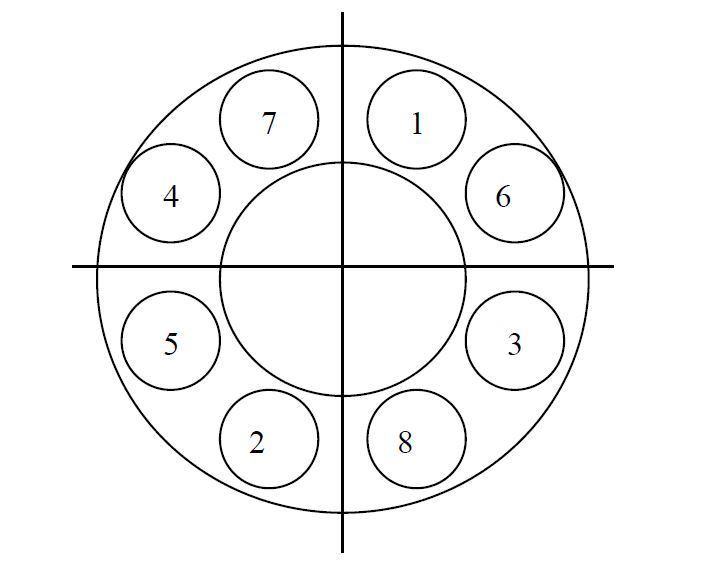

Insert the necessary bolts through the flanges. Depending on the design, the valve may have lugs or holes to accommodate the bolts.

Use crosswise bolt tightening to ensure a secure installation. Other bolt tightening sequences may affect the installation, Do not overtighten.

Gasket Installation (if required):

Some installations may require gaskets between the valve and flanges to ensure a leak-proof seal.

Place the gaskets between the valve and flanges before bolting if necessary.

Final Inspection:

Ensure the valve is securely in place and aligned correctly.

Check for any visible gaps or misalignments.

Testing:

Gradually pressurise the system and inspect for any leaks around the valve.

Keep a close eye on the valve during the initial operation to guarantee its proper function.

Important Considerations:

Installation Distance:

Ensure there is sufficient clearance from any obstacles such as elbows, pumps or tees. It is typically recommended to maintain a clearance distance of 6-8 pipe diameters from such obstacles.

Support:

Make sure the pipe line has enough support to prevent vibrations and load weight from damaging the check valve.

Safety: Always wear suitable personal protective equipment when installing. Make sure the system is de-pressurised and isolated to avoid any accidents.

By following these steps and considerations, you can guarantee the correct installation and operation of a dual plate check valve in a pipeline.

- Related Products

Dual Plate Wafer Type Check Valve

TC0

Fast Delivery: Most orders are shipped within 3-7 days, depending on stock availability. Versatile...

DetailsDual Plate Wafer Type Check Valve with Full Rubber

TC1

Dual plate wafer type check valve with full rubber is usually used in seawater desalination...

DetailsDual Plate Wafer Type Check Valve With Retainerless

TC8

The dual disc check valve with its compact wafer design and low cost have made it a popular...

DetailsDual Plate Lug Type Check Valve

TC6

Lug type double disc check valves typically feature multiple threaded bolt holes around the valve...

DetailsDual Plate Flange Type Check Valve

TC4

Simplified Installation with Flange Type Design Unlike lug type check valves, flange type double...

DetailsDual Plate Full Lug Type Check Valve

TC9

Double disc lug type check valves are designed to ASME, JIS, ISO, AWWA...etc. specifications...

Details- Files Download

Dual Plate Wafer Style Check Valve Installation and Maintenance Instructions

Installation and Maintenance Instructions for dual plate check valve

Download