Cast Iron Dual Plate Wafer Type Check Valve

TC0-CI

CI dual check valve, CI wafer check valve, CI duo check valve, CI non return valve, CI double disc check valve, CI folding Disc Check Valves, CI Twin disc check valve, CI Twin plate check valve

When choosing a double disc wafer type check valve it is important to make a cost-benefit analysis of the specific system. Often focus is to reduce cost and at the same time obtain the lowest possible pressure loss.

CI and DI is cheap material, we chose short face to face standard to make wafer pattern twin plate check valve for cost saving.

Compact design with short face-to-face dimensions minimizes space requirements.

CI is a good material choice in normal working conditions and low pressure.

Cast iron is a time-tested, cost-effective material widely used in low-pressure and ambient temperature applications for dual plate check valves. While it offers high rigidity, its brittleness limits its use to systems with moderate conditions such as water, air, and HVAC pipelines.

In these environments, cast iron dual plate check valves deliver reliable backflow prevention with low installation and maintenance costs, making them an economical solution for building and industrial systems.

Features

- Dual plate check valves is simple and compact, long life and high reliability.

- Variety of Body Designs Available - Wafer Type, Lug Type ,Double Flange Type and Soild lug type.

- Lightweight and Compact Wafer Design:

- Installs between mating flanges with 10 to 20% the weight of flanged swing checks in popular sizes - Saves money in initial valve cost and provides lower installation cost

- Water Hammer Prevention.

- Non Slamming.

- Simplicity installation.

- Abundance inventory and fast delivery.

- Retail acceptable.

- Many special material can be chosen, basically, we usually have CI/DI/WCB/CF8/CF8M material, besides of that, if you need CF3M/ Duplex/Super Duplex, we have some of it in stock. On the other hand, we can do CN7M/ Monel/ Hastelloy C etc.…, however, depend on your quantity, it will need MOQ probability.

- Beautifully packaged:

- Small size packed by carton box, and show material clearly outside

- Big size packed by special plastic wrap, reduce the impact to a minimum.

- Customized special valve.

- Nonscheduled development and design new type.

Dual Plate Check Valve Installation Guide:

When installing a check valve, it can be used in both indoor and outdoor environments. However, if the medium is corrosive or the surroundings are prone to rust, it is essential to select a valve material combination that matches the conditions to ensure durability and safety. For special operating conditions, it is recommended to consult TVCCL’s technical team for professional advice.

Before installation, all debris, oxidation scale, and solid impurities inside the pipeline should be thoroughly removed to prevent interference with the valve’s operation. During installation, the flow direction of the medium must align with the arrow marked on the valve body. The piping should be aligned at the front and rear centers, with flange interfaces kept parallel and bolts evenly tightened. Special attention should be paid to the distance between the check valve and the pump, which should be six to eight times the valve size to ensure stable system performance.

For routine maintenance, regular inspections should be conducted to check for leakage, abnormal noise, or vibration. In addition, the valve should be periodically examined for signs of corrosion, jamming, or other irregularities. Necessary cleaning, dust removal, and residue treatment should be performed to maintain proper equipment operation and extend its service life.

Specification

- Size: 1.5" ~ 60" (DN40 - DN1500)

- Pressure Rating For ASME: 125# ~ 2500# Suit For ASME / MSS / API Flange

- Pressure Rating For ISO: PN10 ~ PN40 Suit For ISO Flange

- Pressure Rating For JIS: 5K ~ 20K Suit For JIS Flange

- Another Flange Standard: BS10 TABLE E / AS2129 TABLE E / AWWA C207

- Material:CI,DI,WCB,CF8,CF8M,ALBC3,A8904A(MOQ)

- Designed in accordance with API 594.

- End Connection: Wafer, Lugged (TC6, TC9), Flanged (TC4)

- (Other flange connection please contact Taiwan Valves Centre Co., Ltd.)

- *Technical information is only for reference. Taiwan Valves Centre Co., Ltd. reserves the right to change without previous notice.

SELECTION GUIDE

1. Clarify Application Requirements and System Conditions

Begin by thoroughly assessing the environment in which the valve will operate. Key considerations include:

• Type of fluid — Is the medium water, oil, gas, slurry, or a corrosive chemical?

• Operating parameters — What are the system’s maximum pressure and temperature?

• Flow behavior — Is there a risk of sudden flow reversal or water hammer?

• Space limitations — Is the piping layout compact or spacious?

These factors help identify the most suitable valve materials and configurations for your system.

2. Select Materials Based on Fluid and Environment

The valve’s body and internal components must withstand corrosion and wear caused by both the fluid and the surrounding conditions. Common material choices include:

• Stainless steel — Excellent for corrosive or sanitary applications.

• Carbon steel or cast iron — Suitable for general-purpose use with non-aggressive media.

• PVC or engineered polymers — Ideal for low-pressure, non-corrosive systems.

Avoid incompatible combinations—such as using brass or mild steel with aggressive chemicals—as this may result in premature failure.

3. Choose the Correct Size and Pressure Rating

Valve sizing should align with the pipe diameter and expected flow rate:

• Proper sizing minimizes pressure drop and prevents turbulence.

• Ensure the valve’s pressure and temperature ratings exceed system requirements to maintain safety and reliability.

4. Evaluate Valve Dynamics and Performance Characteristics

Different wafer check valve designs offer distinct advantages depending on system demands:

• Spring-loaded or dual-plate wafer valves — Provide quick, silent closure to prevent water hammer in high-cycle operations.

• Standard single-plate models — Adequate for slow, steady flow in simpler systems

Seat Material Options for Dual Plate Check Valves

The seat of a dual plate check valve is available in a wide range of materials to meet various media properties, temperature ranges, and pressure conditions. Selecting the right seat material is essential to ensure reliable sealing performance, extended service life, and stable system operation.

Soft Seat Options:

Soft-seated designs provide excellent sealing performance and are typically made from rubber materials such as EPDM, NBR, or FKM (Viton®).

EPDM – Ideal for cooling water, potable water, and general water treatment applications.

NBR – Suitable for oils, air, and other neutral media.

FKM (Viton) – Offers superior resistance to high temperatures and aggressive chemicals, making it ideal for chemical and petrochemical industries.

Metal Seat Options:

For high-temperature, high-pressure, or abrasive conditions, metal seats are recommended to ensure enhanced durability and wear resistance.

Metal seats can be manufactured from the same material as the valve body or from stainless steels such as SS304, SS316, SS410, or hard alloys like Stellite 6. The allowable leakage rate for metal seats varies depending on valve size.

For any special rubber material requirements, please feel free to contact us.

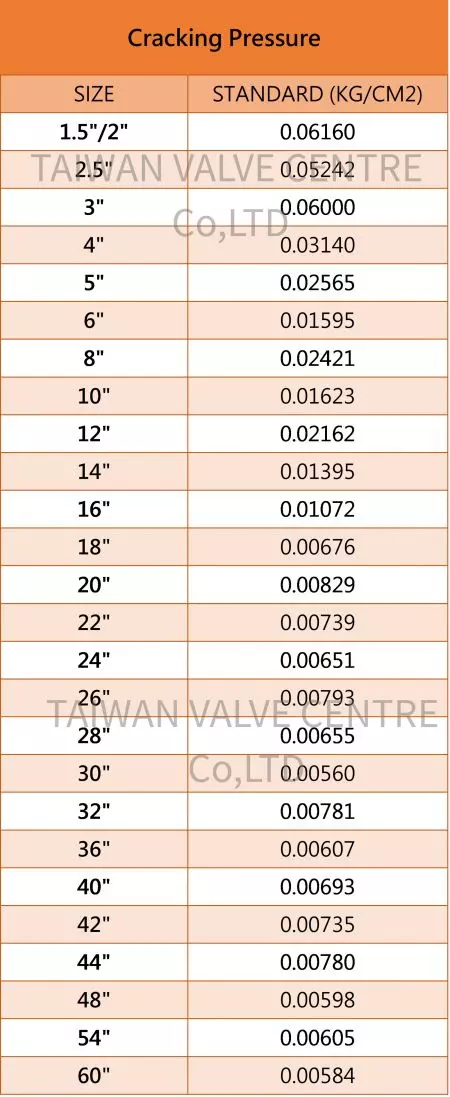

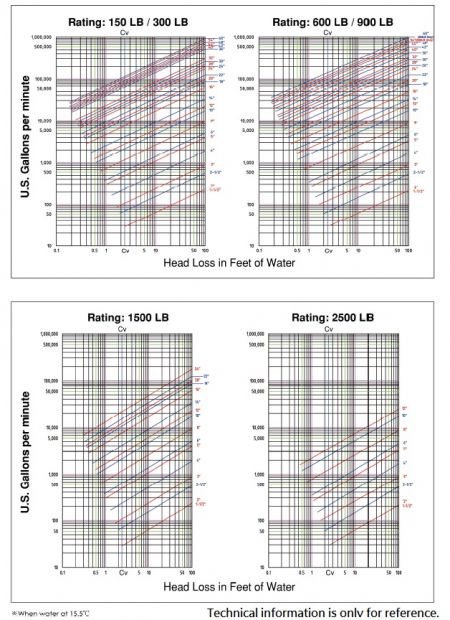

HEAD LOSS

Head loss refers to the loss of a fluid’s total energy (or pressure) as it flows through pipelines or valves, caused by factors such as friction, turbulence, changes in flow direction, and resistance within the flow path. In a dual-plate check valve, head loss is the pressure drop that occurs when the fluid passes through the valve plates and internal structure.

The smaller the head loss, the lower the resistance the fluid encounters when passing through the valve, the higher the flow efficiency, and the less energy is dissipated. This reduces the system’s pumping energy consumption and improves overall operational efficiency. Conversely, larger head loss indicates greater flow resistance and requires the pump to expend more power to maintain the desired flow rate. Therefore, analyzing head loss data is an important step in valve selection to ensure system efficiency, pressure control, and economic performance.

Dual Plate Wafer Type Check Valve Operation

The dual plate check valve consists of a valve body, valve plates, stem, spring, and seat. It opens automatically under fluid pressure, allowing flow from the inlet to the outlet. When the inlet pressure drops below the outlet pressure, the valve plates close automatically due to the pressure differential and spring force, effectively preventing reverse flow.

This type of check valve is widely used in industries such as seawater desalination, shipbuilding, energy, water treatment, HVAC, and electronics. It serves as a safety device to prevent backflow and water hammer when pumps shut down, protecting the system from pressure surges and reverse rotation.

Advantages of Dual Plate Check Valves

Dual plate check valves offer several advantages that make them ideal for modern piping systems. Their compact and lightweight wafer design allows easy installation between flanges, saving both space and weight. The two spring-loaded plates close rapidly when flow decreases, effectively preventing backflow and minimizing water hammer.

Because of their simple structure and few internal components, dual plate check valves require minimal maintenance and provide reliable automatic operation without external power or manual control. They are available in a variety of materials and configurations, making them suitable for water treatment, HVAC, marine, power generation, and industrial fluid systems.

Functions of Dual Plate Check Valves

The primary function of a dual plate check valve is to prevent backflow and ensure that fluid flows in one direction only. Its two spring-loaded plates respond quickly to changes in flow, closing rapidly when flow reversal occurs to protect pumps, compressors, and other equipment from damage.

In addition to backflow prevention, dual plate check valves help maintain system pressure stability, minimize water hammer through non-slam operation, and improve overall energy efficiency. Their compact wafer-type design allows for easy installation and reliable performance across water treatment, HVAC, marine, power generation, and industrial pipeline systems.

Applications

- Dual plate check valves widely used for the basic piping, water, and various piping. For example, Fossil, Nuclear Cogeneration Power. Refining. Pulp & Paper. Mining. Marine. Petrochemicals. Offshore. LNG Cryogenics. Water. Wastewater. Chemical. Aerospace industry. Power Plant. Solar power industry. Reservoirs. TVCCL Dual-plate check valves which can be used in many fields with different uses.

- Dual Plate check valves are also available for general residential use, such as high buildings, apartment, agricultural irrigation, water pipelines, compressors, blowers, pumping pumps, filters, dryers, chillers, boiler systems, refrigerating air conditioning systems, ventilation pipes, pumping motors, sewage, power stations, electronics factories, fire equipment, chemical research, medical equipment, laboratory, ship yachts, major domestic and foreign engineering, factories, etc.

- Double plate check valve, a multi-purpose check valve, can be flexibly mounted on horizontal and vertical piping without any impact.

More Knowledge about TVCCL valve:

TVCCL check valve made of selected materials, each valve we made can offer the material certificate which according to BS EN 10204 3.1. Under the normal using situation, we can guarantee the TVCCL valve is more durable than the other manufacturers. And the performance is more reliable and practical. Using check valve under normal situation all can achieve the non-return effect. However, if the pipeline installation distance is less than 6~8 times the size of the valve, the life of the check valve may be shortened or the valve body and parts may be damaged.

More Knowledge about dual plate check valve:

Cast Iron, price is inexpensive, with ordinary strength and good machinability.

Applicable to the water fluid and normal temperature environment.

The dual Plate Check valve is an automatically opened valve that only allows the medium to flow in the same direction and prevents reverse flow. Automatically open and close when there has pressure generated, no need to handle or other actuation control. Under the action of the pressure flowing in the same direction, the discs are opened, so that the medium can flow in the pipeline; conversely, when the medium flows in the opposite direction, the pressure generated by the medium and the weight of the valve discs act on the seat. When the valve is closed, the check valve will cut off the flow, thereby achieving the effect of backstop and media backflow. Its main function is to prevent backflow of the medium, prevent the pump and drive motor from reversing, and release the container medium. TVCCL's check valve is quickly closed due to the valve flap, which can quickly achieve the effect of the backstop and can effectively reduce the occurrence of water hammer.

- Related Products

Dual Plate Flange Type Check Valve

TC4

Simplified Installation with Flange Type Design Unlike lug type check valves, flange type double...

DetailsDual Plate Lug Type Check Valve

TC6

Lug type double disc check valves typically feature multiple threaded bolt holes around the valve...

DetailsDual Plate Full Lug Type Check Valve

TC9

Double disc lug type check valves are designed to ASME, JIS, ISO, AWWA...etc. specifications...

Details- Files Download

Dual Plate Wafer Style Check Valve Installation and Maintenance Instructions

Installation and Maintenance Instructions for dual plate check valve

DownloadTC0-Dual plate wafer type check valve-CI-125LB.10K.PN10.PN16

Drawing for dual plate wafer type check valve CI CAST IRON 125LB 10K PN10 PN16

DownloadTC0-Dual plate wafer type check valve-CI-BST

Drawing for dual plate wafer type check valve CI CAST IRON BST

Download- FAQ

Q.What Is Check Valve?

TVCCL Check Valve is a dual plate check valve that conforms to API 594. TVCCL is known as one of the leading manufacturers of Valve in Taiwan since we established.A...

Q. How Do Install Double Disc Check Valve In Pipe?

Taiwan Valve Centre Co.,Ltd. is the professional dual check valve manufacturers in the Taiwan. This information concerning the installation and operation...

Q. What Kind Of Material TVCCL Stock For Dual Check Valve?

Materials Stocked for Dual Plate Check Valve by TVCCLTVCCL, a pioneer in valve manufacturing, has been at the forefront of the industry since 1998. Our expertise...

Cast Iron Dual Plate Wafer Type Check Valve - CI dual check valve, CI wafer check valve, CI duo check valve, CI non return valve, CI double disc check valve, CI folding Disc Check Valves, CI Twin disc check valve, CI Twin plate check valve | Made in Taiwan Dual Plate Check Valves Manufacturer | Taiwan Valve Centre Co., Ltd.

Located in Taiwan since 1998, Taiwan Valve Centre Co., Ltd. has been a dual plate check valve manufacturer with all the valves sold to 1,500 clients in 80 countries worldwide. Their main valve products, including Cast Iron Dual Plate Wafer Type Check Valve, dual plate check valves, dual plate full lining type, retainerless check valves, bypass check valves, short and long wafer check valves and spring wafer type for industries, such as oil, shipbuilding, seawater desalination, cooling system and nuclear.

TVCCL has a competitive pricing, reliable quality product and excellent after-sales support, well-down packing. We have received good reputation as being a well-known supplier in supplying reliable quality and competitive price check valves from customers. 20 years of experiences in producing dual plate check valve, excellent after-sales support, OEM / ODM, oil industry, shipbuilding, seawater desalination, cooling system, nuclear industry.

TVCCL, TAIWAN VALVE has been offering customers high-quality and durable industrial check valves for any applications since 1998, both with advanced technology and 25 years of experience, TVCCL, TAIWAN VALVE ensures each customer's demands are met.